Inspired by the work made by Lukas and published by him into this post LINK, I’ve tried to replicate his experiment. I’ve choose to change some ingredients like epoxy and wavelength shifter. He uses E45 epoxy but I’ve preferred E30 because is more clear with better optical properties. He also uses cumarine-102 but cumarine-1 matches better the PPO 2,5-Diphenyloxazole emission spectra.

“Standard mixture” to make a 32gr plastic scintillator sample I use:

- Epoxy E30 part A (base) 20gr

- Epoxy E30 part B (hardener) 12gr

- PPO scintillator 0.32gr

- Cumarin-1 0.032gr

The procedure:

- Heat part A at 80⁰

- Dissolve PPO + cumarin-1 into part A

- Re-heat again solution to 80⁰

- Add part B heating when stirring for 5 minutes

- Pour into a suitable mold like HDPE plastic or silicon

- Put the mold with epoxy over a 3D printed heath bed set at 80⁰C and let it stay for 2h approx. This way the 3D printed heath bed acts as an heather helping the epoxy catalysis.

- I use hot air gun for soldering SMD to heath part A at the start of the procedure simply carefully blowing hot air over the epoxy and stirring to dissolve PPO + cumarin-1

Results show that this kind of epoxy-based scintillator is sensible with alpha beta and gamma rays but especially sensible to beta radiation.

I’ve also made a test to demonstrate the effectiveness of cumarin-1 as wavelength shifter. I’ve made a scintillator without it and… it doesn’t scintillate. Actually it scintillate into UV so I cannot se it!

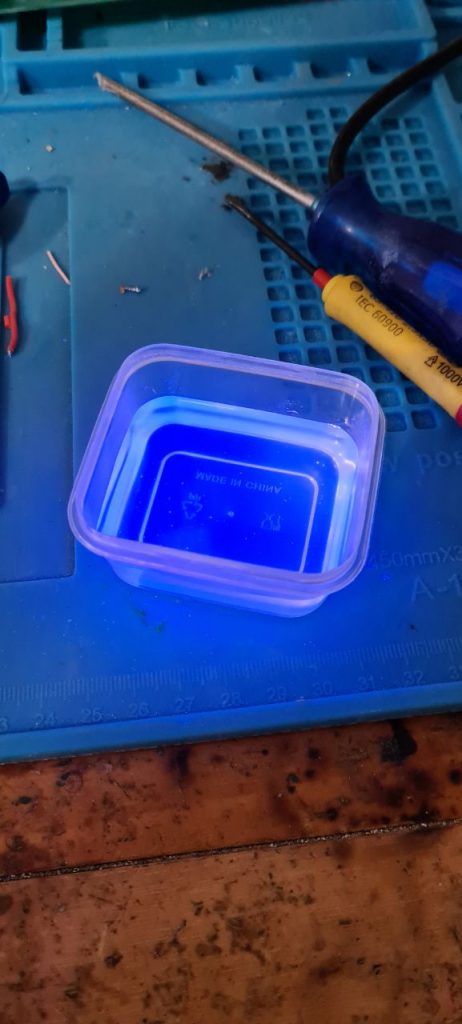

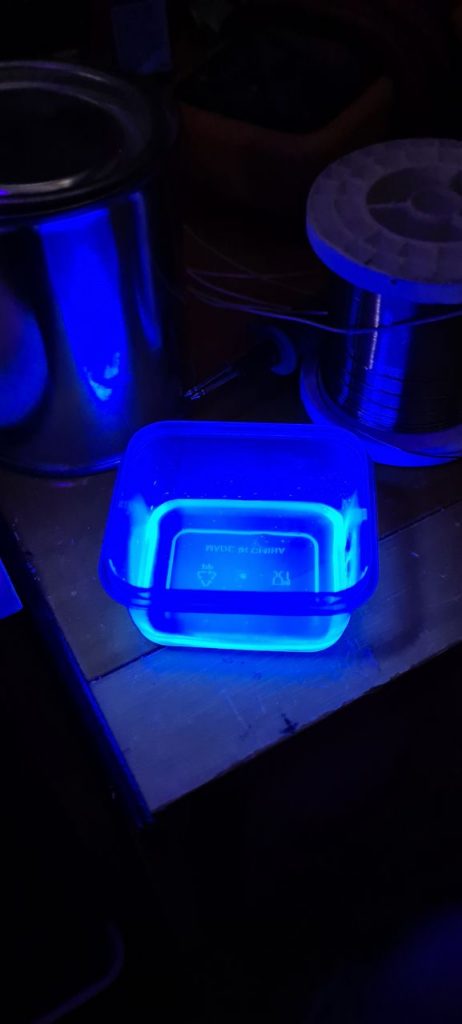

On the left a standard mixture on the right without cumarin-1.

Standard mixture glows bright even in daylight if excited with enough UV from an UV lamp.

The effect is even more dramatic at night.